.jpg) Wet dispersion applications

Wet dispersion applications

FC200S+HRsuspension and emulsion from 200nm to 1mm, minimum sample quantity 0.1ml

|

FC200MHRsuspension and emulsion from 600nm to 1mm, minimum sample quantity 30ml

|

FC200TCsuspension and emulsion from 200nm to 1mm, minimum sample quantity 20ml, heating cell and beaker for temperature controlled analysis up to 150°C |

|

|

|

FC200P-HRSuspensions and Emulstions with particle size range between 200nm to 1000µm. Integrated partistaltic pump for precision and high quantity measurements alike.

|

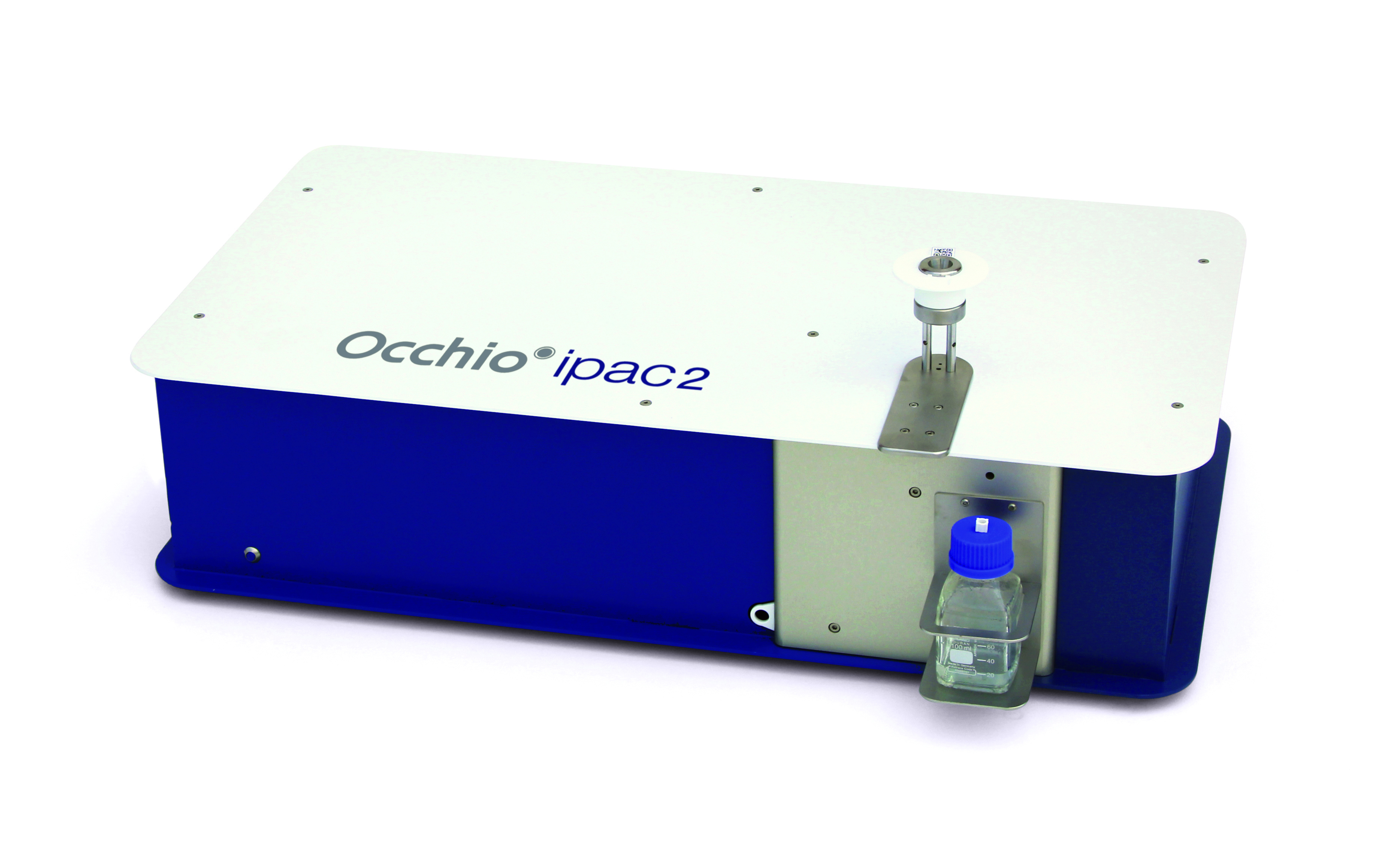

Ipac 2CMP slurry dedicated instrument from 200nm to 500µm, minimum sample quantity 0.1ml |

|

500 NanoDry powder analysis from 200nm to mm range, dispersion surface 90mm. |

|

Zephyr LDAdry powder analysis from 7µm to 5mm, vibrating and air flow dispersion |

|

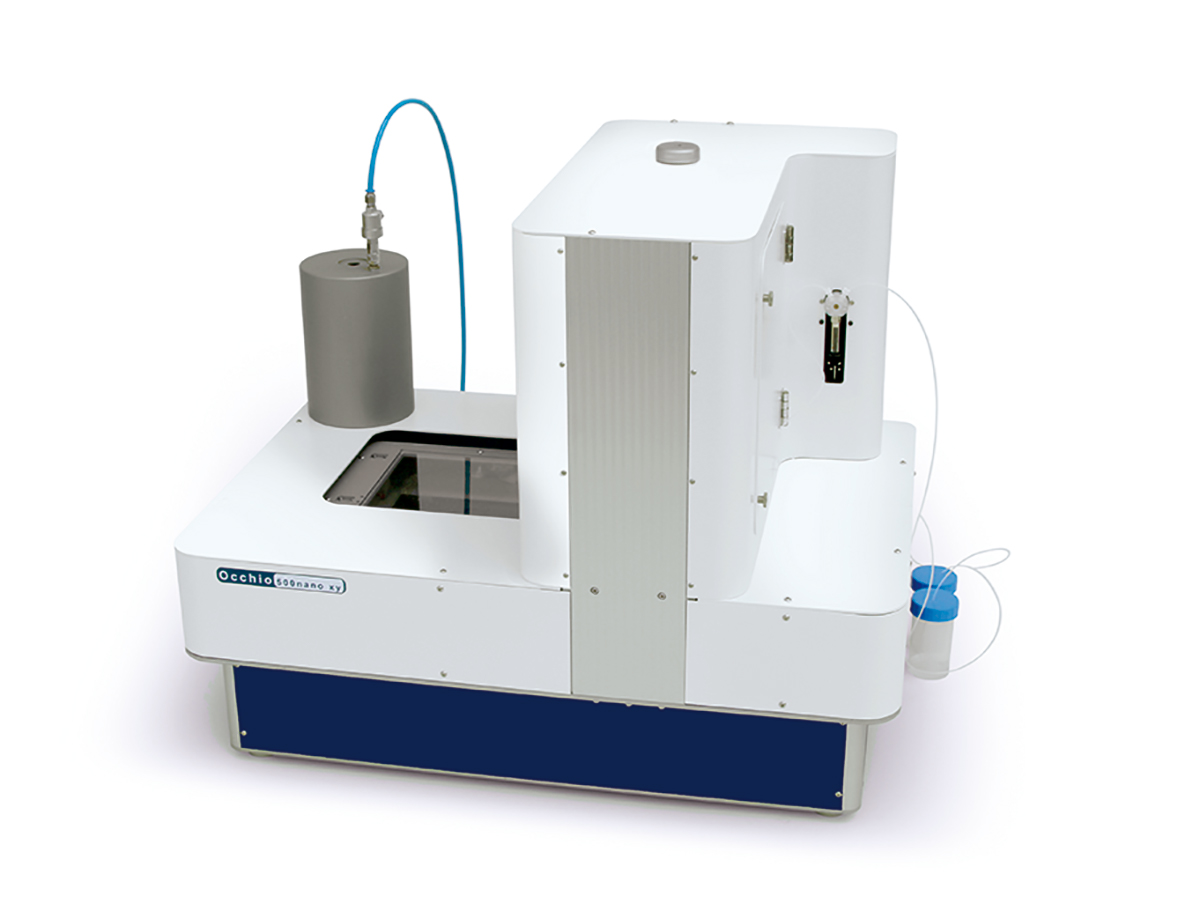

500 nano XYDry and Liquid particle analyses from 200nm to mm range, dispersion surface 140mm. |

|

Zephyr ESR 2dry powder and granules analysis from 30µm to 30mm, vibration and gravity dispersion

|

|

Morpho 3D I New Ithree dimensional size and shape analysis, from 500µm to 10mm, vibration and mechanical dispersion

|

|

Scan 700seed and granule analysis from 10µm to cm range, manual or semiautomatic dispersion |

|

Sievecalverification and calibration of standard sieves according with ASTM norms. |

|

VDD270Dry particle dispersion device for homogenous dispersions every time |

|

Occhio CalistoThe Original Callisto Software is still in use today! Although all new instruments now come with Callisto 3D, the original Calisto software is still supported and eligable for technical support and maintanence.

|

|

Occhio Calisto 3D I New IFaster calculations along with 3D Modeling capabilities. Compatible with all current instruments! Contact us today to see if your instrument is upgradable!

|

|

GranuSize I New IThis software has been designed to work with the Zephyr ESR, ESR 2, and LDA models to provide our users with a solid platform for large volume production quality control operations without the need to train workers. |